In industrial applications, accurate and reliable level measurement is essential for maintaining safe, efficient, and cost-effective operations. Whether managing bulk solids, powders, or liquids, having the right level detection system can make all the difference in productivity and safety. One of the most trusted names in this space is Bindicator®, known for decades of innovation in point and continuous level instrumentation.

What Is Bindicator®?

Bindicator® is a leading manufacturer of level measurement instruments designed for the bulk solid and liquid handling industries. Their products are engineered to monitor and control the level of materials inside bins, tanks, and silos, ensuring smooth plant operations and preventing costly overfills or material shortages.

From grain storage and plastic pellets to cement, chemicals, and food ingredients, Bindicator® devices are built to handle tough environments and a wide range of materials.

Common Bindicator® Products and Technologies

Bindicator® offers a diverse portfolio of level measurement technologies to fit different process needs. Some of the most widely used types include:

1. Point Level Indicators

These devices detect when material reaches a specific point in a vessel—perfect for high- or low-level alarms.

-

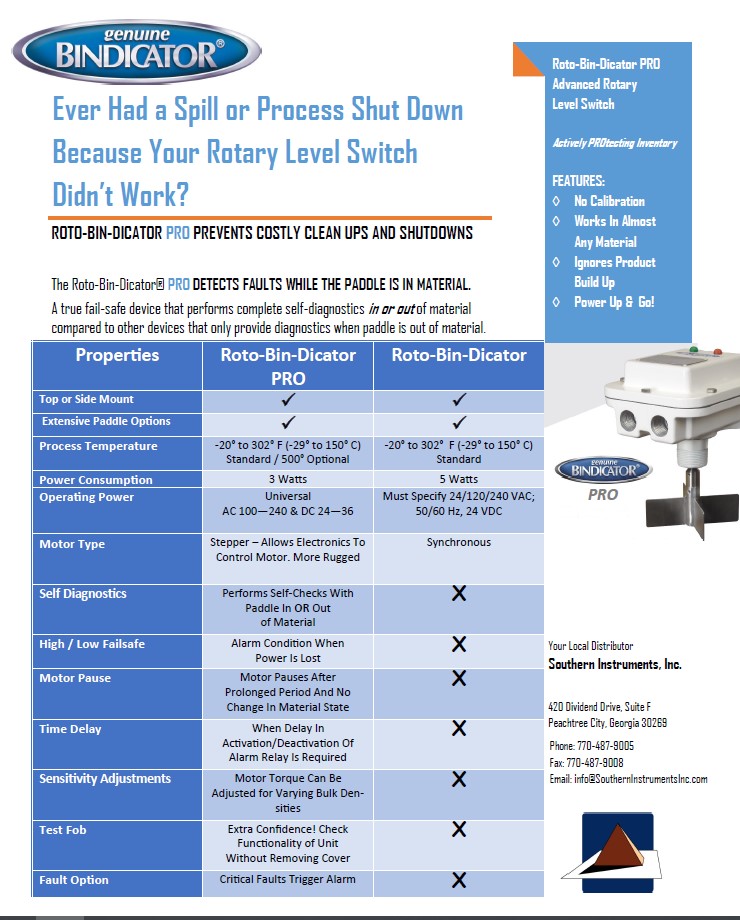

Roto-Bin-Dicator®: A classic paddle switch that activates when material stops the rotating paddle, ideal for powders and granular solids.

-

VRF® II Series: A rugged, versatile version designed for challenging industrial applications.

2. Continuous Level Sensors

For processes requiring ongoing measurement rather than simple point detection, Bindicator® offers continuous level transmitters such as:

-

Pulse Point™ capacitance probes for powders or liquids.

-

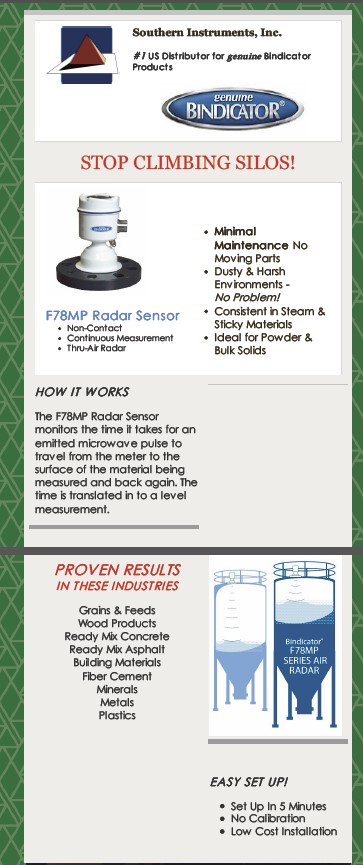

Radar and Ultrasonic Level Sensors for precise non-contact measurement.

-

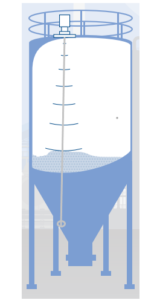

Weight and Cable Systems (e.g., Yo-Yo®) for reliable mechanical readings in tall silos.

3. Accessories and Controls

Bindicator® also provides accessories like digital displays, control units, and mounting hardware to integrate their sensors seamlessly into automated systems.

Benefits of Using Bindicator® Solutions

Choosing the right level measurement technology improves not only efficiency but also safety and product consistency. Bindicator® products are known for:

-

Proven reliability in demanding industrial conditions

-

Easy installation and maintenance

-

Compatibility with control systems (analog, Modbus, or digital outputs)

-

Accurate readings for a wide variety of materials

-

Long service life and minimal downtime

Applications Across Industries

Bindicator® level instruments are used worldwide across industries such as:

-

Cement and aggregates

-

Food and beverage

-

Plastics and chemicals

-

Power generation

-

Agriculture and grain handling

Their versatility and dependability make them a preferred choice for operators needing consistent level control and inventory management.

Partnering with a Trusted Distributor

As an authorized distributor and solutions provider, Southern Instruments, Inc. proudly offers Bindicator® level measurement equipment along with expert support and guidance. Our team can help you select the right technology for your specific process—whether that’s a simple paddle switch or an advanced radar transmitter.

We also provide local technical assistance, start-up support, and ongoing service to keep your systems running smoothly.

Learn More

If you’re looking to improve your plant’s efficiency and safety with proven level measurement solutions, reach out to Southern Instruments, Inc. today.

📞 Contact us to discuss your application needs or request a quote.

– Radar Sensor Continuously Measures Product Level

– Radar Sensor Continuously Measures Product Level