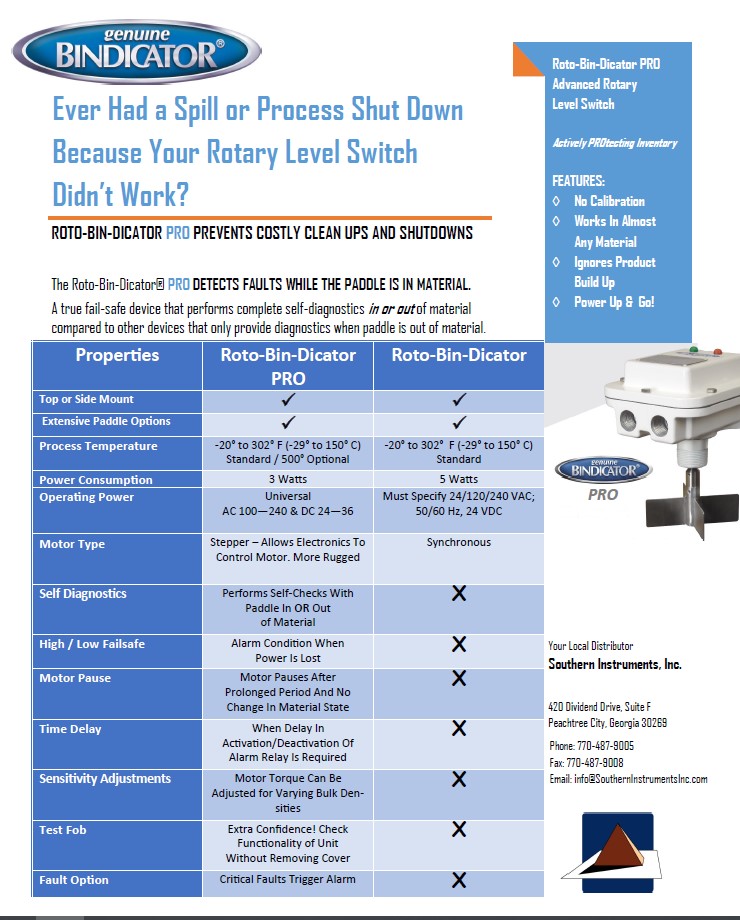

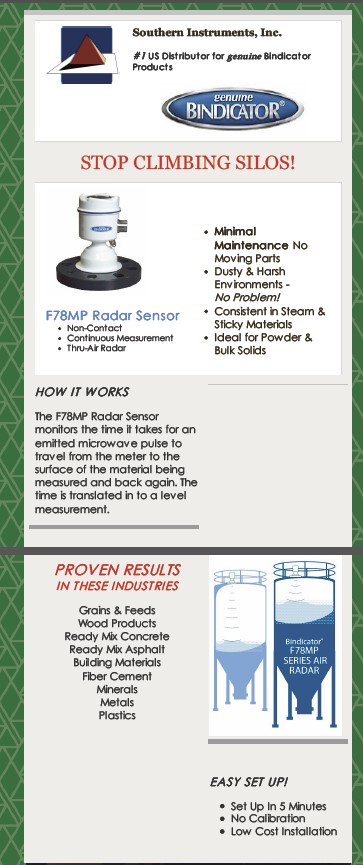

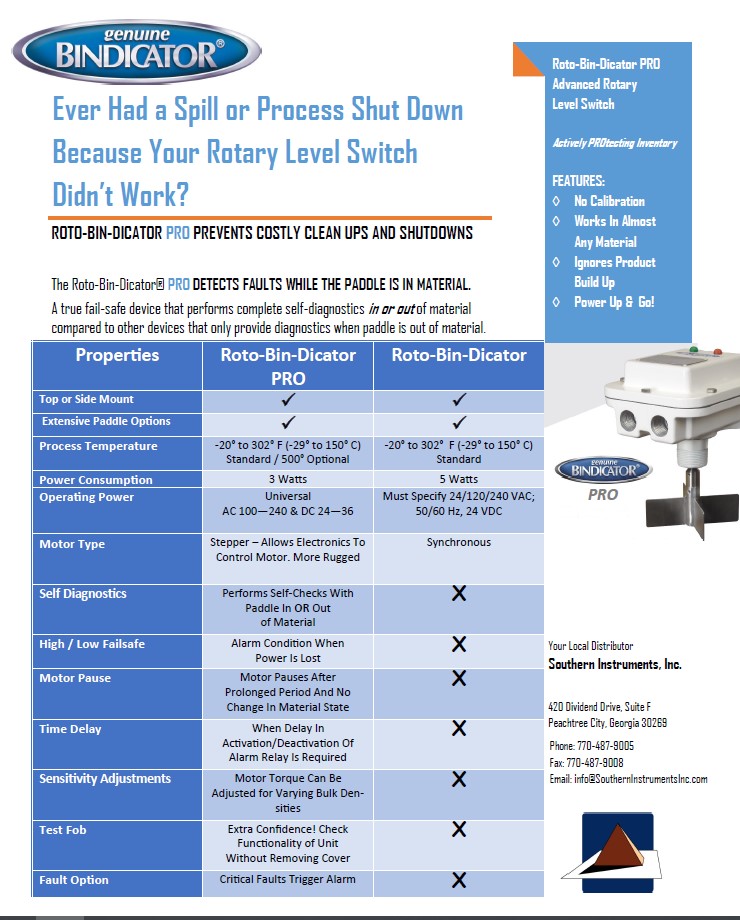

Ever Had a Spill or Process Shut Down Because Your Rotary Level Switch Didn’t Work?

ROTO-BIN-DICATOR PRO prevents costly clean ups and shutdowns.

Download PDF

Ever Had a Spill or Process Shut Down Because Your Rotary Level Switch Didn’t Work?

ROTO-BIN-DICATOR PRO prevents costly clean ups and shutdowns.

Download PDF

Power Plants, Refineries, Cement Plants, Steel Mills, Chemical Industries, Food Industries, Pulp and Paper Manufacturers, Marine Boilers, and anywhere combustion control is required.

ENOTE C Flue Gas Analyzers simply outperform other systems with its unique product design features such as, the 100% gas tight cell construction, high operating temperature, and intelligent software- now including ENOTEC Remote for your android Bluetooth enabled phone or the ENOTEC communicator SME-SMARTBLU. ENOTEC has 40+ years of Combustion Control design & technology experience and offers the highest performance with the lowest cost of ownership.

ENOTE C Flue Gas Analyzers simply outperform other systems with its unique product design features such as, the 100% gas tight cell construction, high operating temperature, and intelligent software- now including ENOTEC Remote for your android Bluetooth enabled phone or the ENOTEC communicator SME-SMARTBLU. ENOTEC has 40+ years of Combustion Control design & technology experience and offers the highest performance with the lowest cost of ownership.

If your current analyzers do not have 100% gas-tight gold brazed sealed cell construction, you are at risk of false higher O2 readings for combustion control. A cemented cell design is prone to cracking and leakage! Reference air leakage to the process measuring side of the cell will show a false reading, which is higher than the actual Oxygen value. This could lead to dangerous combustion conditions!

At least not to Drop a Tape and Measure what you have in your Silos! Why take the chance of Personnel Injury by Climbing Silos to Check the Inventory of your Cement and Fly Ash. With the Bindicator TDR-2000 you can read your Silo Levels from a Display in your Batch House or Control Room.

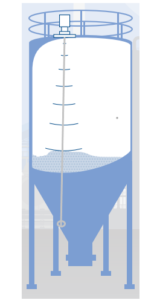

– Radar Sensor Continuously Measures Product Level

– Radar Sensor Continuously Measures Product Level

– Reads Through Air Born Dust

– Display Readings in Batch House or Control Room

– Works Even When Silo Is Being Filled!

– No Maintenance or Cleaning Needed

– Rugged, Weather-Proof Enclosure

– Ignores Material Build-Up on Sensing Cable

– More Accurate Than Hand-Line Reading

Proven in Cement, Fly Ash, Sand & Aggregate!

The Hardware is Very Affordable. Wiring and Sensor installation is Simple and Inexpensive.

Setting up the System can all be done from the Keypad on the Controller/Display. With the Quick Start Guide you will Get the System Up and Running in Less Than an Hour.

The Bindicator TDR-2000 Sensor pulses a Radar Signal from the head of the unit down the Stainless Steel Cable. Where the Cable and the Material in the Silo meet, the Radar Signal reflects and comes back to the Sensor Head. The amount of time that it takes the Radar Signal to travel down and back is measured as the distance. Either a Multi-Channel or Individual Controller/Display then shows each Silo’s Measurement in either “ Feet-of-Product” or “Feet-to-Product”.

And we will get you a Quote for a System that fits your site. We have hundreds of Installations in Cement, Fly Ash, Sand, Aggregate, and many other Powders and Bulk Solids

Keefe Hardy

Southern Instruments, Inc.

420 Dividend Drive, Suite F

Peachtree City, GA 30269

770-487-9005

STOP CLIMBING SILOS!

Gasco Cal GasISO 9001 Certified, Adheres to NIST Standards, Certificate Of Analysis Provided With Each Cylinder

Download PDF

Ever Had a Spill or Process Shut Down Because Your Rotary Level Switch Didn’t Work?

ROTO-BIN-DICATOR PRO prevents costly clean ups and shutdowns.

Download PDF

AccuBin™ is a comprehensive, cloud-based, inventory management system that allows you to remotely monitor inventory through a user-friendly dashboard. This software provides a secure platform to view both real-time and historical trends in your inventory data. AccuBin™ is designed to eliminate the stress and guess work out of bulk solid inventory management.

Download PDF